Synthetic biology—an emerging and often debated field—involves the application of engineering principles to biological systems. While its definition has evolved over time, the European Commission today defines synthetic biology as the use of science, technology, and engineering to facilitate “the design, manufacture, and/or modification of genetic materials in living organisms.”1

Over the past two decades, synthetic biology has fueled advancements across a broad range of disciplines, including agriculture, bioremediation, biofuel production, and chemical manufacturing. Today, it has begun to drive innovation in biopharmaceuticals. GEN spoke with four companies to explore how they are leveraging synthetic biology in their work.

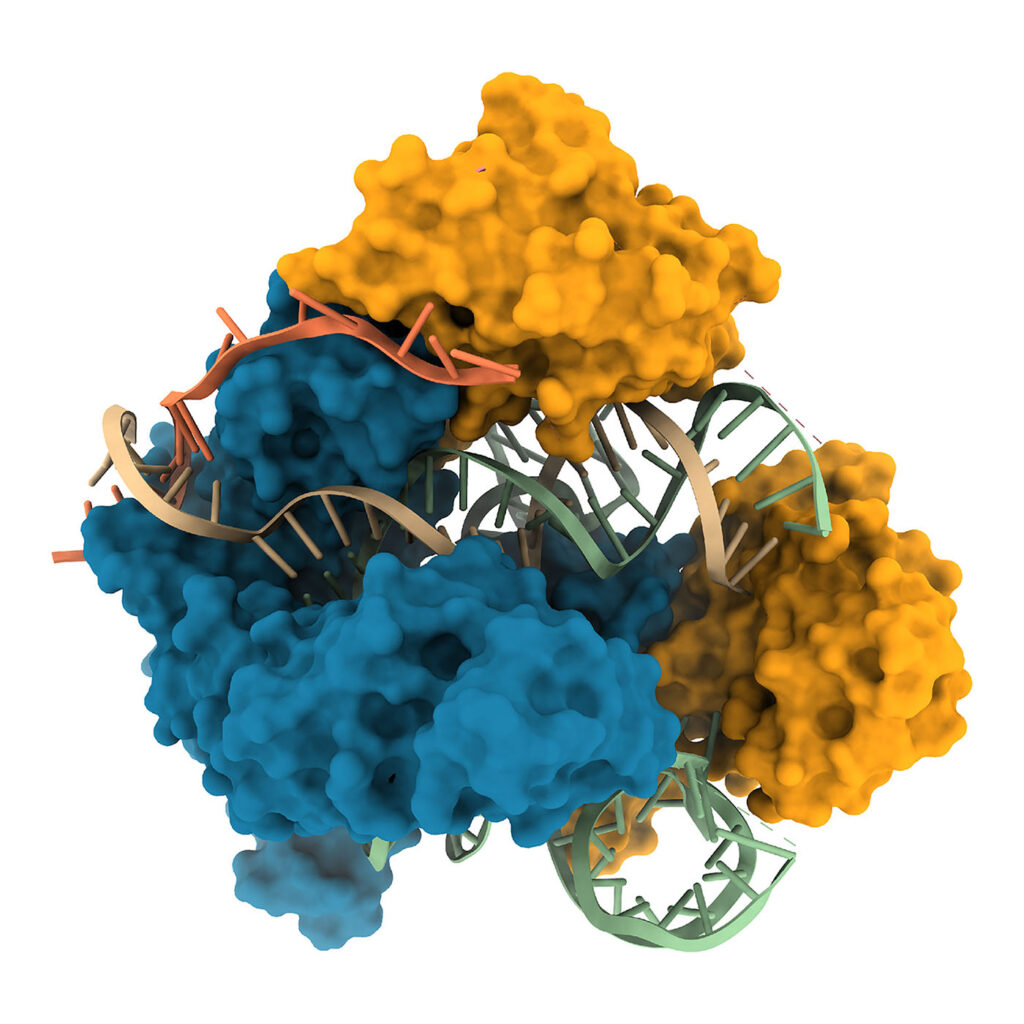

CRISPR for hard-to-reach tissues

Trevor Martin, PhD, co-founder and CEO of Mammoth Biosciences, explains that CRISPR originates from the immune system of microorganisms. And while a wide variety of CRISPR systems exist in nature, the first one discovered involved a protein called Cas9. “Fortunately, CRISPR-Cas9 happens to be a great system,” he notes. “But it has a lot of real limitations.”

Martin emphasizes how Mammoth—spun out of the Doudna lab at the University of California, Berkeley—invested in novel CRISPR systems early on. “The real magic happened when we decided to go to nature to find all of these wacky CRISPR starting points in microbes,” he says. From there, the company employed engineering techniques to enhance these proteins, utilizing machine learning and high-throughput liquid-handling robots to achieve this goal.

What are the advantages of having so many CRISPR systems? According to Martin, Mammoth has developed versions that use proteins a third the size of Cas9 or smaller. These ultra-compact systems are particularly well-suited for delivering gene therapies to hard-to-reach tissues, such as the brain and muscles.

A second advantage of ultra-compact CRISPR systems is that they enable many types of edits. While classic CRISPR editing introduces a double-stranded break, Martin stresses that ultra-compact CRISPR systems allow for the delivery of more complex machinery for more subtle edits—such as the addition or deletion of base pairs.

Martin highlights a Mammoth program called MB-111, which knocks out a gene called APOC3 in the liver that is associated with triglyceride disease. He notes that the program is on track for clinical trials.

Ultimately, Martin sees a rare opportunity to grow Mammoth into a $100 billion company. He explains that once a given CRISPR system proves effective for a specific disease in a particular tissue, only the guide RNA needs to be changed for the next indication. “This is a platform where, once you build one therapy, the second therapy gets easier—which is very different from traditional small-molecule drug discovery,” he says.

“When you think of genetic diseases, you think of dystrophies, Alzheimer’s, and Parkinson’s. These diseases are all muscle and CNS-related,” he notes. “And Cas9 isn’t really effective because it is too big to be delivered there.” In contrast, the company has recently demonstrated very effective muscle editing with an ultra-compact CRISPR system called NanoCas.

Martin is optimistic about the possibility of finally tackling rare diseases of the brain and muscles over the next 10 years with Mammoth’s technology. “We have a shot, which is crazy. I think there is a real shot at treating all diseases where we know exactly which genes to change.”

Programmable medicines

Timothy Lu, MD, PhD, co-founder and CEO of Senti Bio, highlights the challenges associated with most existing cancer treatment modalities—such as T-cell engagers, antibody-drug conjugates, and traditional CAR T-cell therapies.

“These treatments rely on recognizing a single cancer target that needs to be expressed on cancer cells but not healthy cells,” he notes. “However, if these targets are not clean enough—as is often the case in blood cancers and solid tumors—there will be off-tumor killing, leading to side effects and preventing good cancer efficacy.”

This is where gene circuit technology comes into play. Lu explains that gene circuits are another way of applying engineering principles to biology. “They are like computer programs written in DNA that enable cells to make decisions in the body to treat disease more precisely.”

He highlights a specific type of gene circuit, called the “logic gate,” which enables selective killing of cancer cells while sparing healthy ones. “Imagine this as a precise and smart missile that only hits military vehicles while avoiding civilian ones,” he explains.

Senti Bio’s lead program, SENTI-202, is a logic-gated cell therapy that programs natural killer cells to target heterogeneous cancer cells associated with acute myeloid leukemia (AML).

Lu explains that one of SENTI-202’s chimeric antigen receptors is designed to recognize CD33, while the other recognizes FLT3—two markers commonly found on AML cancer cells. In this system, an “OR gate” instructs SENTI-202, “Kill if either CD33 or FLT3 or both are detected.” This logic-based approach enhances the ability to recognize and eliminate malignant cells that express one or both markers, enhancing overall cancer killing.

However, both CD33 and FLT3 can also be found on healthy cells. To avoid toxicity against them, SENTI-202 recognizes EMCN, a marker found on healthy bone marrow stem cells. In this case, a “NOT gate” tells SENTI-202, “Do not kill if you see the EMCN antigen, even when CD33 and FLT3 are present.”

SENTI-202 is currently in a Phase I clinical trial for relapsed/refractory AML and other related indications. As summarized in a recent conference, SENTI-202 is well-tolerated, and multiple patients have experienced complete remissions, with maximum durability reported beyond eight months.

“Correlative data from patients showed targeted killing of AML blasts and AML leukemia stem cells and protection of healthy bone marrow stem cells, consistent with our logic gate mechanism of action,” he notes.

Lu foresees additional applications for Senti Bio’s programmable gene circuits, including solid tumors, autoimmune diseases, and gene therapy.

Drug discovery, engineered

The future of drug discovery will feature less trial-and-error work and more engineering approaches, predict Josh Haimson, co-founder and CEO of Inductive Bio, and John Androsavich, PhD, general manager at Ginkgo Datapoints.

“Synthetic biology is best known for enabling rapid design cycles in engineered organisms,” notes Androsavich. “However, we’re extending that philosophy to small-molecule drug discovery, which is still deeply rooted in biology.” More specifically, this means programming biology with software principles—including designing, testing, learning, and iterating.

In traditional drug discovery, scientists typically begin by formulating a hypothesis about how a molecule might interact with a specific biological target. They then spend weeks or even months synthesizing the molecule and conducting experiments to assess its effects. The results of these experiments inform future hypotheses.

Haimson and Androsavich note that lab-in-the-loop workflows follow the same principles as traditional drug discovery. However, they use AI and automation to significantly expand the number of hypotheses that can be explored and the speed at which they can be tested.

With a lab-in-the-loop approach, AI models explore millions of ideas virtually and prioritize the most informative molecules to test in the lab. Those molecules are then rapidly synthesized and tested using lab automation, and the results from those experiments are fed back into the AI models for learning. This loop runs continuously, making each round of design smarter.

Haimson and Androsavich highlight a three-way partnership that is underway between Inductive Bio, Ginkgo Datapoints, and Tangible Scientific. The goal is to provide a lab-in-the-loop infrastructure that will be available to the entire biopharma industry. As part of this partnership, Inductive will provide AI models for small molecule drug discovery, Ginkgo will bring high-throughput, automated lab assays to test those molecules, and Tangible will orchestrate the secure storage and handling of samples.

“Lab-in-the-loop research is not just about making old processes faster,” emphasizes Haimson. “Instead, the goal is also to enable the discovery of better, safer, and more innovative drugs. By exploring massive amounts of ideas and learning directly from experimental feedback, our platform can suggest directions that teams wouldn’t have thought of.”

Finally, Haimson notes that nearly 40% of biotech companies will be facing cash flow shortages by the end of 2025.2 “Our platform helps them maintain competitive drug discovery capabilities without the massive platform investments that were once required.”

Engineering microbes

Andy Budde, business development associate for Isomerase, stresses the growing importance of engineered microbial biology. “The goal is to treat living cells as programmable platforms by combining biology with the tools of chemistry, engineering, and computer science,” he says.

He explains that Isomerase’s clients typically approach the company with the intention of modifying and scaling enzymes, proteins, peptides, small molecules, and natural products. The company supports the development of each client’s ideas into real-world products for clinical and commercial use.

“At Isomerase, we have worked extensively with natural products, which remain a rich and underexplored source of active pharmaceutical ingredients,” notes Budde. However, the company also employs engineering principles to design new possibilities—ranging from breakthrough medicines to more sustainable production methods, such as biocatalysis.

Isomerase employs a range of tools to modify microorganisms and molecules, including machine learning and strain engineering, in which microbial hosts are reprogrammed at the genetic level to improve yields, robustness, and scalability. The company’s machine learning-driven EvoSelect® platform enables the directed evolution of enzymes into more efficient and scalable biocatalysts.

Isomerase also employs fermentation to improve the commercial viability of biopharmaceutical products. “The use of microbes offers several advantages over traditional chemical reactions,” Budde says. “Namely, it doesn’t require harsh solvents or surfactants, making it more cost-effective and environmentally friendly.”

Does Isomerase prioritize sustainability, innovation, or efficiency? “In practice, these goals are interconnected,” says Budde. “A sustainable process is most often more efficient, and new biological routes can unlock compounds that were previously inaccessible.”

References

- Heidari R, Shaw DM, Elger BS. CRISPR and the rebirth of synthetic biology. Sci Eng Ethics. 2017;23(2):351-363. doi: 10.1007/s11948-016-9768-z.

- Focus on fundamentals to bounce back. EY Biotech Beyond Borders Report 2025. EY Insights. Page 7.